Download Documents

Cuemaster BrochureReleased in the early 1980's this is the last in the line of a series of portable professional tape recorders made in Australia. From the original Byer 77 through to the Cuemaster 77 MkVC there had been 30 years of development and four companies: Byer, Rola, Plessey, and CEI.

This is a CEI publicity photo

Recently I acquired a stereo version of this model, serial number 100. It was not in good shape, one amplifier channel had been cannibalized, some push button switches in the other channel need repair or replacement, the capstan motor had ceased and the heads need re lapping. These are just the obvious faults.

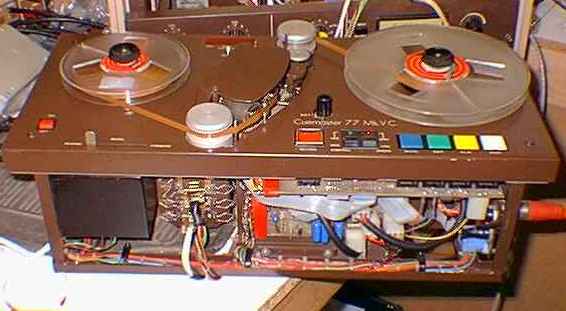

This is a picture of the amplifiers and the case. The amplifier without any "guts" is on top of the case.

At this stage I don't have any spare parts or documentation for this machine so I thought a good first step might be to determine if the capstan motor could be repaired. From about the middle of production of the Rola "77" Mk III a PAPST capstan motor was used so it was likely that I would have suitable spare parts if the motor was damaged. Removal of the motor is quite straight forward:

1. Loosen the four captive hex head screws in the deck cover plate.

2. Remove the four screws which hold the deck in the case.

3. Disconnect the amplifier cables from the deck.

4. Disconnect the capstan motor cable from the deck.

5. Remove the three nuts which retain capstan motor.

6. Carefully withdraw capstan motor from the rear of the deck.

After removing the mu-metal shield the motor was fixed in a vice, there is a sturdy flat mounting plate which can be held by a vice as long as the vice jaws are kept away from the motor mounting points. With the bearing cover removed a de-greesing agent was sprayed on the motor shaft. Using quite a bit of force to rotate the motor back and forth by hand I was able to remove the motor shaft from the bearing. A further degreasing of the mating parts was done followed by removal of the degreasing agent then a small amount of grease was applied before re-assembly. The motor could now be spun by hand quite easily. After mounting the motor back on the deck plate it was time to perform the first test, till this time I hadn't powered up the machine so didn't know if there were any major problems with the deck electronics.

This is just before the first test.

POWER UP, no flashes, bangs, or smoke -- so far so good. Holding the tape overrun switch arm in so the tape motion functions are not negated I checked each function and they seemed to work. Next I tried a tape to see if there were any tape handling issued that need addressing. For this test a junk tape was needed as tape damage is likely. The brake tension springs needed adjustment to eliminate tape spillage when stopping tape motion after high speed spooling in either direction. Next a quick playback test was performed and this confirmed that high frequency performance not the best so it's likely that the heads either need re lapping or replacing.

Here my MkVC is playing a tape.

The heads are showing a considerable amount of ware.

This completes only the first step in the restoration of this tape machine. Whether I continue the work or use the machine for spare parts will depend on what parts or machines I find in the near future. For the moment at least this is the only MkVC I have in my collection and as it is a stereo machine full restoration is the preferred option.