Download Documents

MkII Series Brochure Product Brochure Operation Manual #1 Operation Manual #2 Service Manual

The additional features of the Byer "77" Mk II in comparison to the Byer "66" Mk II and the earlier Byer "77" truly made it a professional tape recorder. These features are:

1. Direct drive capstan and spool motors (no belts).

2. Push button / solenoid operation.

3. Speed 7 1/2 and 15 ips.

4. Four winding speeds in each direction.

5. "EDIT" mode to make it easy to thread and cue.

6. The "EDIT" and winding modes are controlled by the "SHUTTLE CONTROL" rotary switch.

7. Shuttle monitor control sets the position of the tape lifter, for tape monitoring while winding.

8. Tape threading line on the deck.

9. Slanted "S" tape path for fast and easy threading.

10. Spool locking caps, particularly important when the machine is mounted vertically in a 19" rack.

11. Tape run out switch to stop tape run or winding modes in the absence of any tape.

12. Each main sub-unit, amplifier, deck, and optional auxiliary spooling unit are 19" rack mounting.

13. Play-Safe key-switch used to lock-out unintentional recording.

14. Remote control socket, for "STOP", "PLAY", and "RECORD" functions.

15. Auxiliary spooling unit socket (a unit with motor spacing for 10 1/2" spools).

16. Bias adjustment.

17. 600 ohm balanced input and output.

18. Balanced inputs for both microphone and high impedance line.

19. Tape/Source monitoring whilst recording.

20. Separate controls for Tape/Source selection of metering and monitoring.

21. Click-less mode change between "PLAY" and "RECORD" without interruption to tape motion.

22. Mu-metal head covers are used on both the Record and Replay heads.

23. VU meter with very good transient indication.

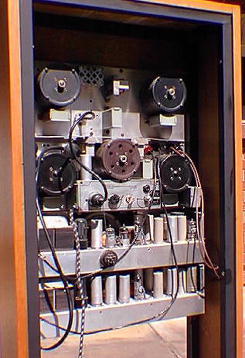

The Byer "77" Mk II Deck

This shot gives you a good look at the head block and the Mu-metal head shields.

Byer Industries designed high quality recording equipment which was simple to operate, reliable, and easy to maintain. The tape deck in the Byer "77" Mk II was a vast improvement over the original Byer "77" as many of the features normally only found in professional console machines of the period had been incorporated into the Byer "77" Mk II. I believe that the simplicity of operation was brought about by the combination of the slanted "S" tape threading path, the open access to the head block, and the use of controls which have more than one function.

Threading tape on many open reel machines not the easiest task and I think that in many cases these tape transports were designed by people who didn't work as operators in a broadcast environment. The design of Byer "77" Mk II transport must have had some input from people who used the equipment as it is the easiest machine to thread that I have ever used. The only other tape machines that are similarly easy to thread are the later Mks of this machine, the Rola Professional "77" Mk III made first by Rola after they took over Byer Industries and then made by Plessey following their take-over of Rola. During the early 1970's Plessey further developed the model 77 series. The 77 Mk IV was the first in the series to use a transistorised amplifier.

From an operational view point the combination of two or more functions into each control position gives the deck a deceptively simple appearance but still allowing the full functionality. The way this was achieved was to combine a rotary control with a push button in the centre of the control knob. The first of these controls is the "PLAY" push button, the associated rotary control is a three position switch which has the positions "OFF" (mains), "7 1/2 ips", "15 ips". Further the lower section of this control is a tape guide which is free to rotate. The next control is the "STOP" push button, here the rotary control is an eleven position switch called the "SHUTTLE CONTROL" which allows winding and editing modes to be selected. With the "SHUTTLE CONTROL" in the centre "STOP" position the deck functions "PLAY" and "RECORD" may be used. When the "EDIT" positions are selected the break solenoid is energised to release the breaks, a small amount of torque is applied by the spool motors, and the tape run-out switch is ignored so that tapes can be threaded, edited or cued. In addition to the "EDIT" function there are four winding speeds in each direction. Finally the "RECORD" push button has the "SHUTTLE MONITORING" knob as the associated rotary control. The "SHUTTLE MONITORING" control allows the operator to manually set the position of the tape lifter so that tasks such as high speed monitoring during winding or cuing can easily be performed. Lesser used functions such as bias adjustment and the "PLAY-SAFE" switch were placed on the rear panel of the deck. The Bias/Erase oscillator is located on the deck and a 12BH7 tube is used for this circuit.

The Byer "77" Mk II Amplifier

This gives you a close-up of the amplifier controls and the rear of the chassis.

The amplifier panel has three types of balanced input, 50 ohm for a microphone, 600 ohm line level, and 100 kohm bridging input. All of these inputs are connected to a single input transformer, the 600 ohm and 100 kohm connections incorporate fixed attenuators so that similar signal levels result from each input. The recording level is set with the "RECORD GAIN" control and the signal level can be accurately monitored using the VU meter when the "METER/600ohm" switch is set to "RECORD". During "RECORD" or "PLAY" the play output level can be set using the "PLAY GAIN" control this level can be checked with the VU meter if the "METER/600ohm" switch is set to "PLAY". Control of the monitoring loudspeaker is separate from the "METER/600ohm" switch. So that the amplifier panel was not cluttered with too many controls a simple idea was used to combine both the Record/Play signal selection and the volume setting of the monitor speaker. Byer Industries used a special centre tapped volume control, the centre tap of the resistance track was connected to 0V and the record and play signals were each applied to one end of the potentiometer. This resulted with a control which when set to the centre of its travel will give no output, rotate it fully anti-clockwise and you have maximum output of the Record channel while rotating it fully clockwise you have the full output of the Play channel.

The tube complement of the Byer "77" Mk II amplifier is:

1 x 5Y3GT, 3 x 12AU7, 1 x 12AX7, 3 x EF86, and 1 x N78.

Stereo Byer 77 MkII Tape Recorder

|  |

The unit shown here is the best piece in my collection as very few of the "77" Mk II units were optioned for stereo operation. This model was one of the earliest if not first Australian made professional stereo tape recorder. This unit is one of two once owned by the ABC Concerts Department in Adelaide and was in service till the about mid 70's.

In fact a friend of mine was working at the Collinswood studios in the late 70's and gave me a guided tour. Whilst I was there I saw the pair of machines just before they were to be despatched to storage in preparation for auction. Two years later they were offered at auction and my unit was sold for $100. I however was not the purchaser, I arrived late to the auction and the unit had been bought by another friend of mine. At the time I offered him double what he had payed but he wasn't interested. Ten years later, in 1990, I met up with him again and I mentioned that I had just bought a different model Byer tape recorder. He then asked me if I was still interested in the stereo unit as it had been in storage all this time he done nothing with it. I jumped at the opportunity and he only wanted $100!!

This is one of the few audio tape machines that has a total of five motors. There is also a total of nineteen tubes in this unit!

So far I have been unable to precisely date the unit. The Byer "77" Mk II series was made between early 1957 and early-mid 1962. On the chassis the serial number label indicates that it was made by Rola at the South Melbourne factory so it can be no earlier than late 1957 when Rola had taken over Byer Industries and before the factory was relocated. My guess is 1958. This unit is serial number 990 this, however, does not indicate that there were at least 990 of these stereo machines made. The serial number is for the standard mono "77" Mk II, the stereo version was only an option and not a separate manufacturing run. This unit is rare!